Pharmaceutical bottle caps are an important part of pharmaceutical packaging and play a vital role in the overall sealing of the packaging. There is no doubt about the importance of the lid. There are various types of lids on the market. What are the main materials commonly used?

In terms of material, there are two common raw materials for medicinal bottle caps: polypropylene and polyethylene. Most of the lids are mainly made of polypropylene, which is a colorless, odorless, non-toxic, translucent solid substance with a temperature range of -30 to 140 °C. It is resistant to corrosion by acid, alkali, salt solution and various organic solvents below 80 °C. Bottles produced with this material are glossier, but less flexible.

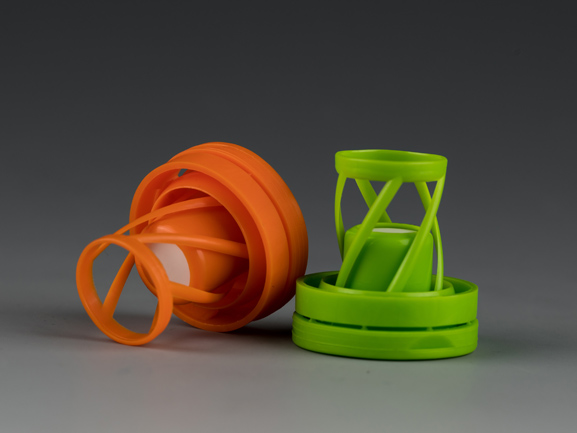

Polyethylene is a thermoplastic resin obtained by polymerization of ethylene. It is odorless, non-toxic, feels like wax, has excellent low temperature resistance (minimum operating temperature can reach -100~-70°C), and has good chemical stability. Resistant to most acids and bases (not resistant to oxidizing acids). It is insoluble in common solvents at room temperature, with low water absorption and excellent electrical insulation. The lid of this material is used more in the packaging of effervescent tablets, and its soft characteristics are very suitable for spring lids.

On the whole, the commonly used materials for medicinal bottle caps are mainly polyethylene and polypropylene. Both materials have good stability. The difference lies in flexibility and temperature resistance. The specific material selected depends on the material of the packaging itself. It depends on the actual application.

没有评论:

发表评论