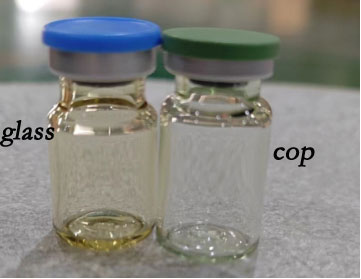

Irradiation sterilization is a critical step in pharmaceutical, medical, and food packaging industries to ensure that products are free from harmful microorganisms. While materials like glass and some plastics can change in appearance or degrade after exposure to radiation, Cyclo Olefin Polymer (COP) bottles remain remarkably stable. This stability makes COP an ideal material for sensitive applications. In this blog, we will explore why COP vials do not change color after irradiation sterilization and why they are preferred for sterile packaging solutions.

after Irradiation Sterilization

What is Irradiation Sterilization?

Irradiation sterilization uses ionizing radiation—such as gamma rays, electron beams, or X-rays—to kill bacteria, viruses, and fungi. This method is particularly effective because it penetrates deep into materials without the need for high temperatures, making it suitable for heat-sensitive products.

However, ionizing radiation can affect some materials by altering their molecular structure. For instance, certain plastics may discolor, become brittle, or lose mechanical strength. These changes can compromise product appearance and integrity, posing risks in applications that require high material performance and transparency.

What is COP?

Cyclo Olefin Polymer (COP) is a high-performance thermoplastic known for several desirable properties:

RTU(ready to use) 2ml COP vial

Optical clarity: Similar to glass, making it suitable for transparent containers.

High chemical resistance: Compatible with sensitive substances, including pharmaceuticals.

Dimensional stability: Resists deformation under varying temperatures and conditions.

Low extractables: Reduces the risk of contamination, making it ideal for medical and biological storage.

COP has become the material of choice for injectable drug containers, pre-filled syringes, diagnostic kits, and laboratory equipment, where sterility and product integrity are critical.

Why Do COP Vials Resist Color Change After Irradiation?

Stable Molecular Structure

COP is engineered with a highly stable carbon backbone. Unlike some polymers, it lacks certain chemical groups—such as aromatic rings or carbonyl groups—that are prone to reacting with radiation energy. As a result, irradiation does not trigger molecular breakdown or rearrangement that would cause discoloration.

Resistance to Oxidation

Oxidation reactions are one of the main culprits behind color changes in irradiated materials. COP’s structure is resistant to oxidation, meaning fewer byproducts form that could affect color or transparency.

Minimal Crosslinking or Chain Scission

In many polymers, irradiation causes crosslinking (linking of molecular chains) or chain scission (breaking of chains), which can alter the material's appearance and performance. COP exhibits minimal crosslinking under radiation exposure, preserving its clarity and physical properties.

Low Additive Content

Some plastics contain additives, like dyes, stabilizers, or plasticizers, which may degrade under radiation and cause discoloration. COP typically has low or no additives, ensuring that it remains stable during sterilization.