Horses, like all animals, sometimes require medication to maintain their health and treat various conditions. Administering medication to horses can be a challenging task, and one of the most effective tools for this purpose is the equine oral syringe. This blog will explore the importance, functionality, and benefits of equine oral syringes, as well as considerations for their packaging and use.

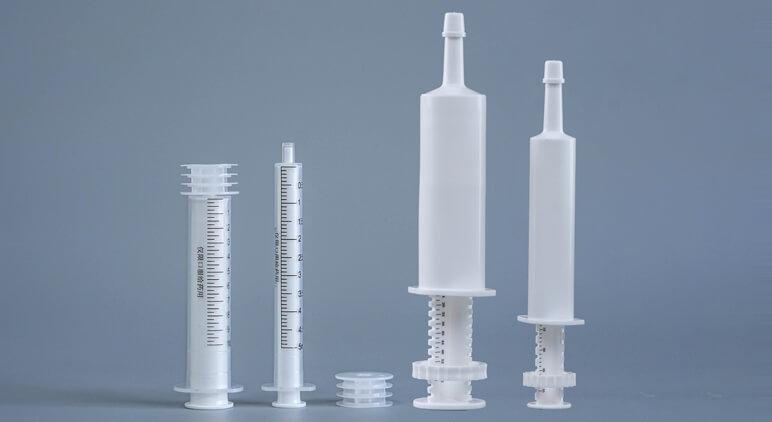

60ml equine oral dosing syringe

What is an Equine Oral Syringe?

An equine oral syringe is a specialized device designed to administer liquid medications, supplements, or dewormers directly into a horse's mouth. These syringes are an essential tool for veterinarians and horse owners, enabling precise and efficient delivery of necessary treatments.

Key Features and Benefits

Precision in Medication Delivery

Equine oral syringes are designed to deliver accurate doses of medication, ensuring that the horse receives the correct amount each time. This precision helps in effectively managing the horse's health and prevents underdosing or overdosing, which can lead to ineffective treatment or adverse effects.

Ease of Use

These syringes are user-friendly, making it easier for horse owners and veterinarians to administer medication. The syringes are typically equipped with a long nozzle that reaches deep into the horse's mouth, ensuring that the medication is delivered correctly and minimizing the risk of spillage.

Versatility

Equine oral syringes can be used for a variety of purposes, including administering liquid medications, nutritional supplements, and dewormers. This versatility makes them an indispensable tool in equine healthcare, suitable for both routine and emergency treatments.

Reduced Stress for Horses

Administering medication using an oral syringe is generally less stressful for horses compared to other methods, such as injections. The non-invasive nature of the veterinary paste syringe helps keep the horse calm and cooperative during the process, which is beneficial for both the animal and the handler.

Conclusion

Equine oral syringes are essential tools for administering medication to horses, offering precision, ease of use, and versatility. Proper packaging and best practices in use are crucial to ensuring the safety and effectiveness of these syringes.

By understanding the benefits and considerations for equine oral syringes, horse owners and veterinarians can make informed decisions that enhance the health and well-being of their horses. This targeted approach not only helps in effectively managing various health conditions but also promotes a stress-free and safe environment for administering necessary treatments.