While much attention is given to temperature control in biopharmaceutical cold chains, one often overlooked factor threatens drug integrity: material shrinkage. When standard vials contract unevenly during freezing, microscopic gaps form at the stopper interface, creating pathways for contamination. This silent failure mode has led to costly product recalls and efficacy loss in mRNA vaccines, protein therapies, and cell-based medicines.

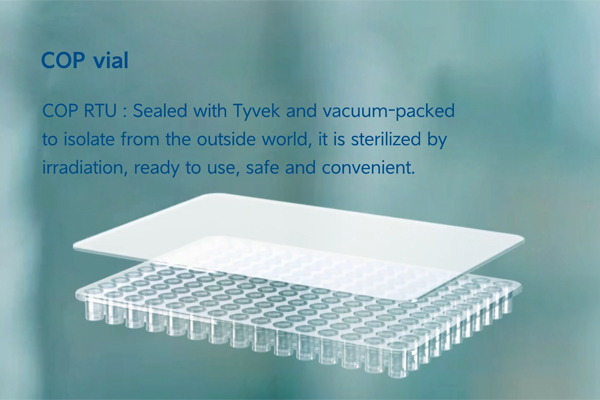

Polymer Vial 2ml 5ml 10ml for cell and gene therapies

Why Traditional Solutions Fall Short

Glass vials, despite their widespread use, exhibit brittle fracture behavior below -80°C and suffer from mismatched shrinkage rates with elastomeric closures. Even cyclic olefin copolymer (COC) alternatives show 1.5-2% dimensional change at liquid nitrogen temperatures—enough to break sterile barriers. The pharmaceutical industry has long accepted these compromises, implementing workarounds like:

Overly thick stoppers (increasing particulates)

Secondary packaging (adding cost/complexity)

Narrower temperature bands (limiting flexibility)

The COP Advantage: Precision Engineering at Molecular Level

COP vials achieve breakthrough performance through polymer crystallinity control. During manufacturing, the cycloolefin chains align into a thermodynamically stable configuration that delivers three key benefits:

Near-Zero Hysteresis Shrinkage (0.3% at -196°C vs. 1.8% for COC)

Coefficient of Thermal Expansion (CTE) matching with bromobutyl stoppers (Δα < 0.5×10⁻⁶/°C)

Anisotropic Contraction that maintains critical seal zones

Independent testing by NSF International confirmed COP vials maintain >95% seal integrity after 50 freeze-thaw cycles (-196°C to 25°C), compared to <60% for glass counterparts.

Real-World Impact on Advanced Therapies

Case Study: A leading mRNA vaccine producer reduced lyophilization cake defects by 73% after switching to COP vials, attributed to:

Elimination of "cold cracks" during -70°C storage

Consistent inner vial geometry for precise fill volumes

No delamination risks during rapid thawing

Future-Proofing the Cold Chain

As gene therapies push storage requirements toward -150°C and regulatory agencies tighten container closure integrity (CCI) standards, COP's material science advantages position it as the only viable solution for next-generation requirements.

For pharmaceutical engineers evaluating cryogenic packaging, the question is no longer whether to adopt COP vials, but how quickly they can requalify their cold chain logistics around this enabling technology.