In addition, although some components in the packaging materials can be obtained in the extraction test, they will not migrate into the preparation in the migration test and stability test; but the extractable may be degraded or other Components react, and these degradation products or reaction products can migrate into the formulation. Therefore, based on the extraction test, the real preparation should still be used for migration test.

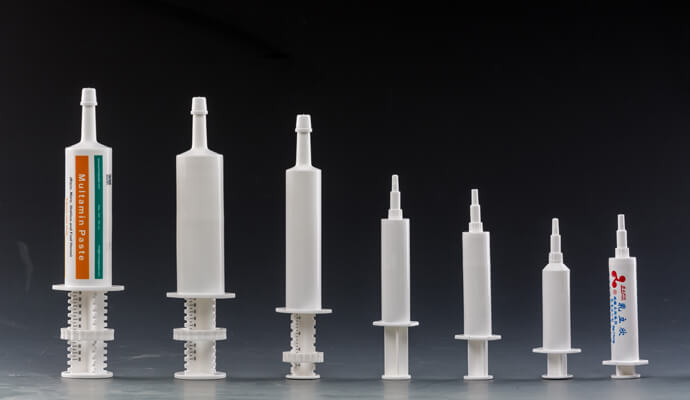

empty vitamin c tubes

Migration tests are used to monitor substances that migrate from the packaging material and enter the formulation. Usually through accelerated or long-term stability tests (note that the preparation should be in full contact with the packaging material) to increase the corresponding detection target compound (derived from the understanding of the packaging component material composition or the extractable information obtained by the extraction test) to obtain the drug The information of the extract contained in it includes the type and content level of the extract.

In addition, if the packaging material is composed of different layers of materials (3-layer and 5-layer co-extruded film bags), it is not only necessary to evaluate the possibility of the innermost component migrating into the drug, but also the middle and outer components should be considered. Possibilities in drugs; At the same time, it must also be proved that the ink or adhesive in the outer layer will not migrate into the drug. Semipermeable material packaging should be researched on the outer layer of ink or adhesive will not migrate into the drug.