Oral liquid medications, supplements, and health drinks are an integral part of daily wellness and medical treatments. Whether it's a prescription drug or a convenient vitamin solution, how these liquids are packaged plays a significant role in ensuring safety, efficacy, and ease of use. Over the years, oral liquid packaging has evolved with both functional and aesthetic considerations in mind. In this blog, we'll dive into the importance of packaging for oral liquids and explore some of the latest trends and innovations in the field.

The Importance of Oral Liquid Packaging

When it comes to liquid formulations, packaging isn't just about convenience or appearance—it's a critical component in maintaining the integrity and safety of the product. Here are some key factors that make packaging crucial for oral liquids:

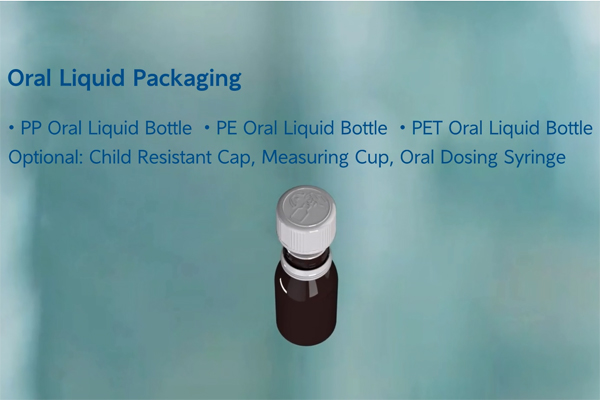

Preserving the Product's Integrity: Oral liquids are prone to contamination, degradation, and evaporation. Proper packaging materials can help protect the product from external factors like light, air, and moisture, ensuring that the liquid remains potent until it reaches the consumer.

Safety and Child Resistance: Child-resistant caps and tamper-evident seals are essential for preventing accidental consumption, especially for liquid medications. The packaging must not only be functional but also designed to deter children from accessing the product.

Ease of Use: The packaging should be user-friendly, especially for elderly or disabled individuals. Measuring cups, syringes, and other dosage control systems can make administration easier, preventing over- or under-dosing.

Child-Resistant and Tamper-Evident Features:

Child-resistant closures have been around for a while, but they’ve become more sophisticated with advancements in design. New mechanisms, such as push-and-turn caps and tamper-proof seals, are being used to enhance safety without compromising ease of use for adults.