Cow mastitis is a common disease in dairy farming and requires medical treatment to relieve symptoms and restore health. Due to the special site of administration, cow mastitis drugs are often packaged in intramammary syringes.

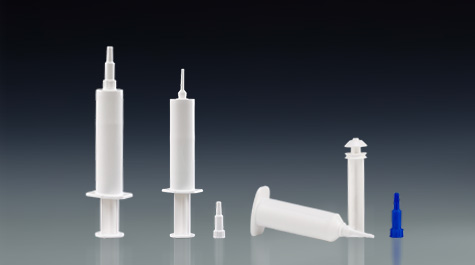

The plastic syringe has two functions of drug storage and administration, and it can maintain the airtightness of the overall package under the action of the protective cap and the push rod. Open the protective cap, push the push rod, and it turns into a drug delivery tool, which is very convenient to operate. The common specifications of this kind of packaging are 5ml, 8ml, 10ml, 13ml, etc., and can also be customized according to your needs. The unique design can avoid contamination and cross-infection, and ensure the purity and effect of the drug, which has a good guarantee for the treatment of dairy cows.

Taken together, intramammary syringes, as a packaging method for cow mastitis drugs, have the characteristics of safety, convenience, and waste reduction. In addition, this kind of packaging is also used in cockroach medicine, uterine infusion medicine, pet nutrition cream and so on.