Mastitis is a frequently-occurring disease in the dairy cow breeding process, the main cause of which is the invasion of pathogenic bacteria, such as trauma and poor milking techniques. Poor environmental sanitation, improper feeding and management, hormone imbalance, breast defects, etc. The use of veterinary syringe to treat cow mastitis is a commonly used treatment method at home and abroad.

The pathogenic microorganisms of dairy cow mastitis are more complex, including more than 80 kinds of bacteria, fungi, mycoplasma, yeast and viruses. In general, Staphylococcus, Streptococcus and Escherichia coli account for more than 70% of clinical mastitis, followed by Corynebacterium pyogenes, Pseudomonas aeruginosa, Necrobacterium, Nocardia, Klebsiella and so on. Asymptomatic recessive mastitis is higher than clinical mastitis, with an incidence of about 50% of the entire herd. About 90% of recessive mastitis is caused by Streptococcus and Staphylococcus.

Mammary perfusion, also known as local drug delivery, is a commonly used treatment method for cow mastitis at home and abroad. The method uses a syringe to inject medicinal liquid into the diseased breast area, so that the medicine directly acts on the pathogenic area or the diseased part in the breast area. Various types of mastitis.

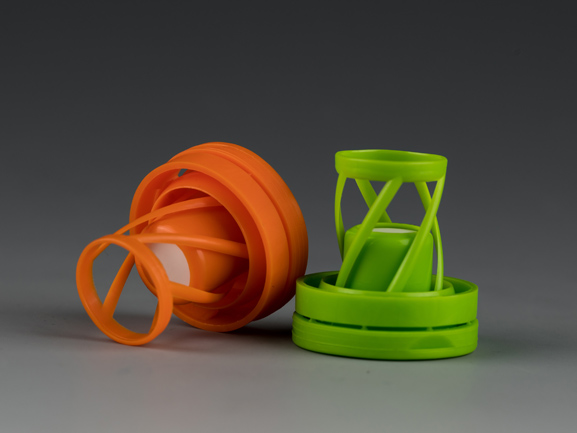

The specifications of intramammary syringe are mostly 5ml, 8ml, and 10ml. The needle is made of soft LDPE raw material, which can reduce the discomfort caused to the cow during administration. The thinner tip can pierce the udder of the cow to complete the administration.