Plastic bottles are a common form of packaging for medicines, generally consisting of a bottle cap and a bottle body. As an important part of packaging, the importance of pharmaceutical bottle caps is becoming more and more prominent. On the basis of ensuring the integrity and sealing of packaging, it also shows a diversified development trend in terms of functions. Below, let's reveal the special functions of medicinal bottle caps together.

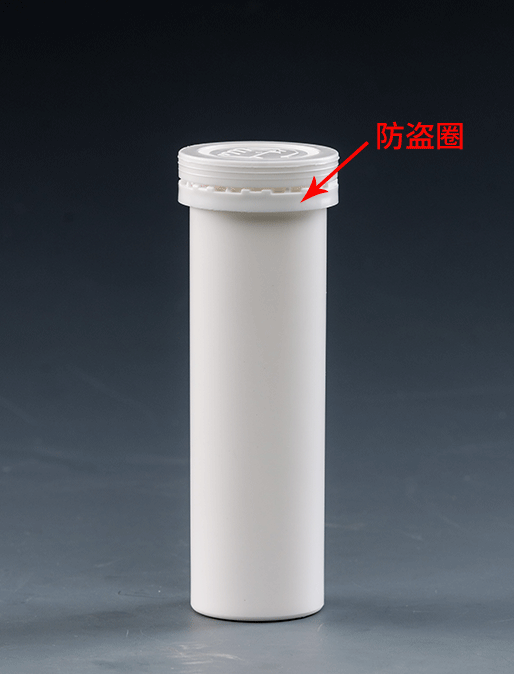

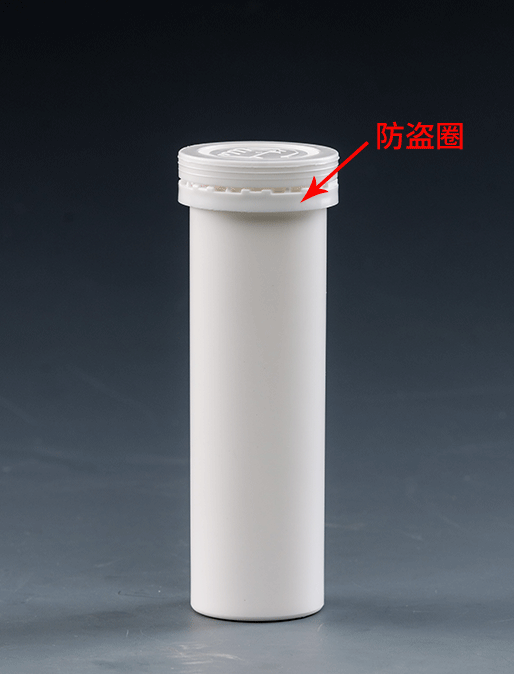

medicine cap

Anti-theft ring

This feature is relatively common, inspired by the anti-theft ring on the beverage bottle. A small circle is connected under the bottle cap, which is also called a one-time broken anti-theft ring. When the cap is unscrewed, the anti-theft ring will fall off naturally and remain on the bottle. It can be judged whether the medicine has been maliciously opened according to the state of the anti-theft ring.

anti-theft ring on cap

Key points: Xinfuda's medicinal bottle caps have an anti-theft ring, which automatically falls off after opening, and the connection has passed 300 breakpoint tests, making it easy to open.

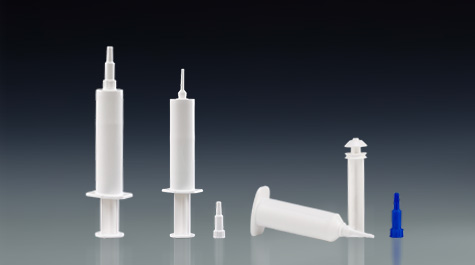

Moisture-proof

Solid drugs such as tablets and capsules have strict requirements on the moisture-proof performance of the packaging. In addition to selecting production materials with good barrier properties to prevent external water vapor from invading, the moisture-proof inside the packaging is also important. The moisture-proof cover cleverly uses the space on the top of the cover to design a small medicine compartment to store desiccant and absorb moisture to maintain the stability of the internal environment of the package.

desiccant cap

Key points: Xinfuda’s moisture-proof cover uses imported desiccant, and the moisture content of the finished product is ≤2%, which is higher than the national standard of 2.8; the saturated moisture absorption rate of the desiccant is between 24% and 28%, ensuring that the drug is kept in good condition.

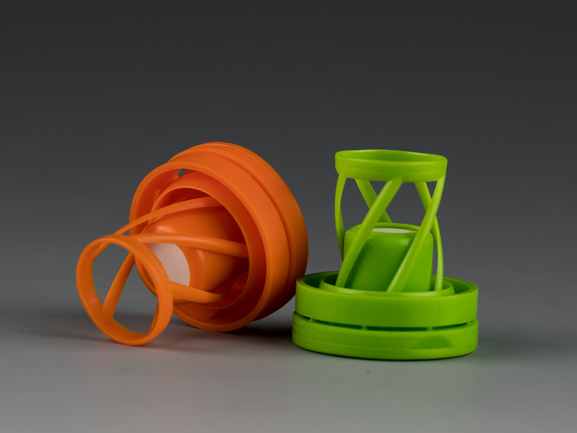

child resistant

This is a more popular type of lid in recent years. It adopts an inner and outer double-layer structure design, and it must be opened by pressing down and rotating at the same time. Such a cover can effectively prevent children from opening the package at will and accidentally eating medicines.

28mm child resistant cap

Key points: Xinfuda's child-proof cap adopts a universal 28 mm, which can be adapted to plastic bottles or glass bottles. According to the different characteristics of the two materials of plastic and glass, a corresponding special design has been made on the internal structure of the bottle cap, and the sealing effect is excellent. better.

At present, the special functions of medicinal bottle caps include three aspects: moisture-proof, child-proof and anti-theft. With the continuous changes in market demand, the design of the caps is also constantly updated and iterated. We will wait and see what special functions will be added in the future. Xinfuda will also do more explorations on the function of the lid to provide better security for the drug.