In the intricate world of pharmaceutical packaging, every component is meticulously designed to ensure the safety, integrity, and effectiveness of the medication it houses. Among these components, the PP28 oral liquid bottle cap stands out as a versatile and essential element. Widely used in the packaging of various liquid medications, this cap plays a crucial role in maintaining the quality and usability of the products. In this blog, we delve into the reasons behind the widespread use of the PP28 cap and its significance in pharmaceutical packaging.

plastic bottle with cap for liqoid medicine

Understanding the PP28 Oral Liquid Bottle Cap

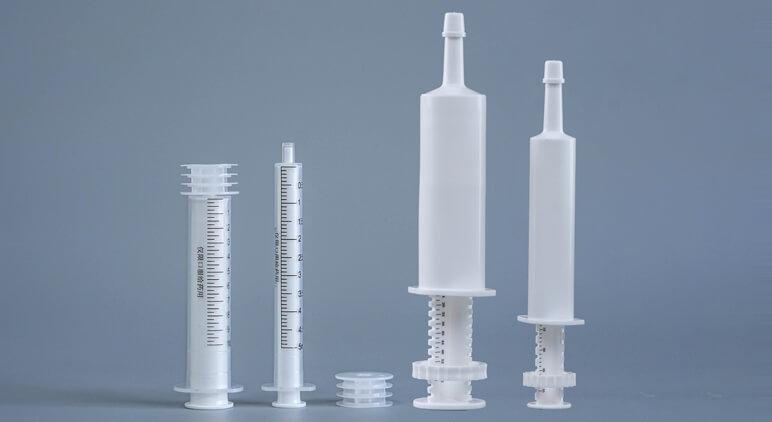

The PP28 oral liquid bottle cap is specifically designed for bottles that contain liquid medications. The "PP" stands for polypropylene, the material used to manufacture the cap, while "28" refers to the 28mm diameter of the bottle neck it fits. This cap is not just a simple closure; it incorporates several advanced features that make it ideal for pharmaceutical applications.

28mm child resistant cap for glass liquid

Key Features and Benefits

Child-Resistant Mechanism:

Safety First: One of the paramount concerns in pharmaceutical packaging is preventing accidental ingestion by children. The PP28 cap often includes a child-resistant mechanism that requires a specific combination of pressing and turning to open. This feature ensures that children cannot easily access the medication, providing an added layer of safety.

Tamper-Evident Seal:

Ensuring Integrity: The tamper-evident seal is a critical feature of the PP28 cap. It provides a visual indication if the bottle has been opened or tampered with. This assurance is vital for both consumers and manufacturers, as it guarantees that the medication remains untouched and uncontaminated until it reaches the end-user.

Leak-Proof Design:

Maintaining Sterility: Liquid medications must be kept sterile and free from contamination. The PP28 cap features an airtight seal that prevents leaks, ensuring that the contents remain uncontaminated and preserving the medication's efficacy.

Ease of Use:

User Convenience: Despite its safety features, the PP28 cap is designed for easy opening and resealing by adults. This balance of security and convenience makes it user-friendly, particularly for patients who need to take their medication regularly.

Applications in Liquid Medication Packaging

The PP28 oral liquid bottle cap is utilized across a broad spectrum of liquid medications, thanks to its versatile design and functionality. Some of its common applications include:

Cough Syrups:

Protection and Convenience: Cough syrups are frequently used by both children and adults. The PP28 cap ensures that these medications are safe from tampering and accidental ingestion while providing ease of access for regular use.

Nutritional Supplements:

Preserving Potency: Liquid vitamins and nutritional supplements require secure packaging to maintain their potency. The airtight and leak-proof design of the PP28 cap ensures these supplements remain effective throughout their shelf life.

Prescription Medications:

Ensuring Safety: Prescription liquid medications often come with specific storage and handling requirements. The PP28 cap meets these demands by providing a secure, tamper-evident closure that maintains the medication's integrity.

Conclusion

The PP28 oral liquid bottle cap is a prime example of how thoughtful design and material selection can significantly impact pharmaceutical packaging. Its widespread use across various liquid medications highlights its versatility and effectiveness in ensuring the safety, integrity, and usability of pharmaceutical products. As the industry continues to advance, the PP28 cap will remain a vital component in delivering high-quality, safe, and effective liquid medications to consumers.