The effervescent tube is a special packaging used to store large-dose medicines such as effervescent tablets and candy tablets. Most of the medicines in this type of tablets contain auxiliary materials such as starch, which are prone to fragments, deliquescent and adhesion after being damp. As a special packaging for these drugs, how can the effervescent tube be moisture-proof?

The moisture inside the drug packaging mainly comes from two aspects. One is the certain water molecules contained in the tablet itself during the compression process. The other is that in the packaging process, the raw materials will also contain a small amount of water molecules. Generally, in order to maintain the dryness inside the package, a desiccant is placed in the medicine bottle. These desiccants will absorb the moisture inside the package and maintain the stability of the medicine.

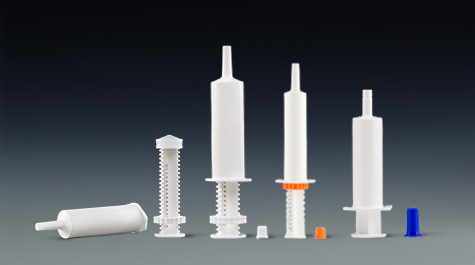

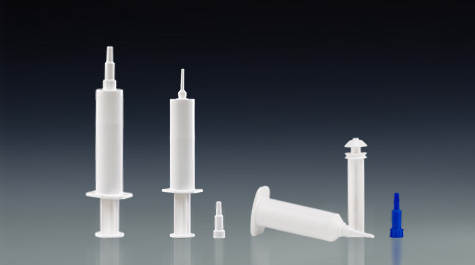

144mm*29mm effervescent tube supplier

But the effervescent tube is different from ordinary medicine packaging. Due to the larger dosage form of the tablets and the stacked storage method between the tablets, there is no extra space inside the packaging for the desiccant. After a special design, a small drug warehouse is designed on the cap of the effervescent tube to store silica gel and molecular sieve, which is what we usually call a moisture-proof cap. Such a design can not only absorb internal water vapor and maintain the stability of the drug, but also prevent direct contact between the desiccant and the drug, which is more conducive to the safety of the drug, and to a certain extent, it also avoids the risk of children ingesting the desiccant by mistake.

The effervescent tube guarantees the stability of the medicine with its unique moisture-proof cover. At present, the design of the moisture-proof cover has also been applied to more medicine packaging and played a more important role.