With the improvement of people's health awareness, the degree of attention to pharmaceutical packaging has also increased. Tablets and medicine bottles are commonly used to pack solid medicines such as tablets, pills, and capsules, and their quality is directly related to the safety of medicines. The country has also formulated corresponding standards for packaging quality to ensure drug safety. Among the quality standards, easy oxide detection is a very important one.

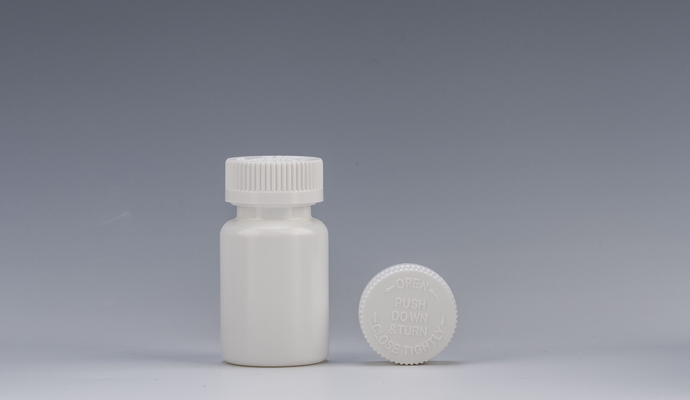

45ml plastic medicine bottle with CRC

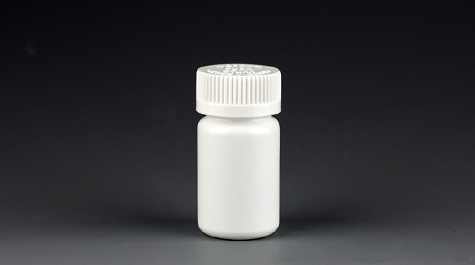

50ml pharma desiccant bottle

Easily oxidized substances refer to substances that are prone to chemically react with oxygen in ordinary environments. The common ones are metals that are prone to rust. In the pharmaceutical packaging industry, they generally refer to substances that are prone to oxidation reactions with oxygen, such as organic matter, reducing agents, Sulfur, phosphorus, etc. The control of easy oxides is of great significance to ensure the quality of the drug within the validity period, prevent the chemical reaction between the precipitated reducing substances and the drug, and affect the efficacy and safety of the drug.

For the detection of easy oxides in tablet vials, there are detailed regulations in the quality standard of YBB00122002-2015 "Oral Solid Pharmaceutical High Density Polyethylene Bottles": precise measurement of 20ml of water for test solution, precise addition of potassium permanganate for titration 20ml of solution (0.002mol/L) and 1ml of dilute sulfuric acid, boil for 3 minutes, quickly cool, add 0.1g potassium iodide, place in a dark place for 5 minutes, titrate with sodium thiosulfate titrant (0.01mol/L), and titrate to the end point At the time, add 5 drops of starch indicator solution, continue titration until it is colorless, and receive the water blank solution in the same way. The difference between the two consumption of sodium thiosulfate titrant (0.01mol/L) shall not exceed 1.5ml.

The above is the test method for the easy oxides of the tablet vial in the domestic quality standards for pharmaceutical packaging materials. This test is only one of the quality standards. To meet the standard requirements, it needs to be in appearance, microbial limit, abnormal toxicity, and production environment. Comprehensive control and other aspects.