Effervescent tablets are a kind of pharmaceutical dosage forms containing disintegrants. There are many kinds of them, such as aspirin effervescent tablets for antipyretic and analgesic, Chinese patent medicine Jinlian Qingre effervescent tablets, multi-dimensional effervescent tablets for supplementing vitamins or trace elements, etc. As a special item, it has very strict requirements on packaging effervescent tubes. If it gets wet, it will easily lead to deterioration of medicines, affect the efficacy of medicines and even human health. In order to avoid this situation, we can avoid the effervescent tube from getting damp from the following aspects:

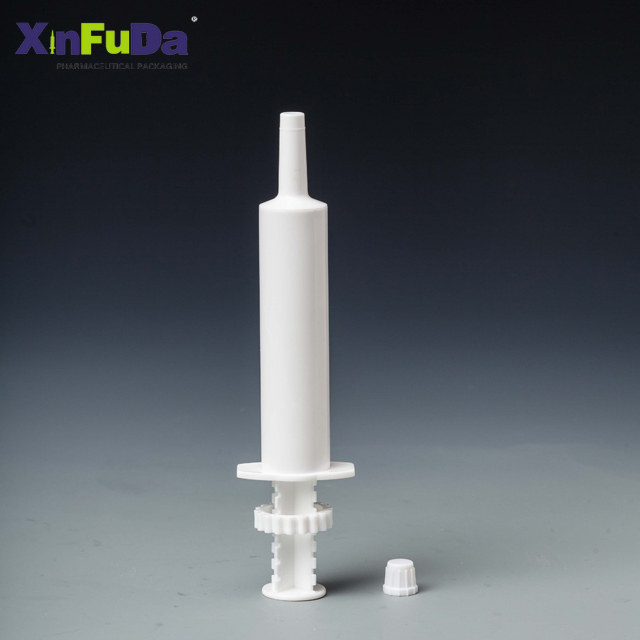

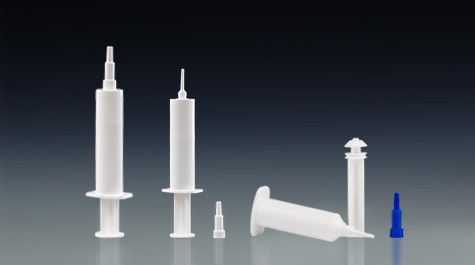

144mm*29mm effervescent tube packaging

1. Sealing: If the inside of the effervescent tube is damp, first consider whether the sealing of the effervescent tube is qualified. The factors affecting the sealing performance mainly depend on the precision of the mold and the strict control of each production link. The material of the effervescent tube generally has moisture resistance, which can block the external water molecules, but if the seal is not tight, it is easy to cause water vapor to enter the inside of the effervescent tube, causing the medicine to be damp and deteriorate.

2. Dosage of desiccant: The desiccant of the effervescent tube is mainly a mixture of silica gel and molecular sieve. If the inside of the effervescent tube is still damp when the overall sealing is good, it may be because the amount of desiccant is not enough to completely To absorb the moisture of the medicine itself, consider increasing the amount of desiccant.

3. External environment: The moisture inside the effervescent tube is also related to the external environment. If the storage environment is too humid, it is easy to get damp inside the effervescent tube, so try to choose a dry and ventilated place during storage.

If we encounter moisture in the effervescent tube later, we can try to analyze these aspects to avoid this situation and ensure our stability during drug storage.